NEDI LABO

Presentation of “Nedi Labo”

A form of our responsibility

Tohoku bolt has a R&D department. Not only the development of new products, we constantly taken care of all product functionalities even in current usage. That is one of the” forms” of responsibility which a manufacturing company has to assume, in order to carry out a safe and reliable infrastructure contribution. In Nedi Labo, we are developing several types of fastening products, not only bolts and screws. We also study and analyze the strengthening of Fractography. (Fractography: to observe the fracture surface of the damaged object, and to analyze to obtain the destruction causes and mechanism information.)

When the fastening products are broken, we are able to study and analyze the destruction causes ourselves by observation of the destruction surface. This result helps us to give feedback to the improvement of the materials selection, in order to improve the product quality and our manufacturing technology.

Each facility allows us to work in research and development in the multilateral approach.

- Observation application research based on expertise

- Investigation of the mechanical properties

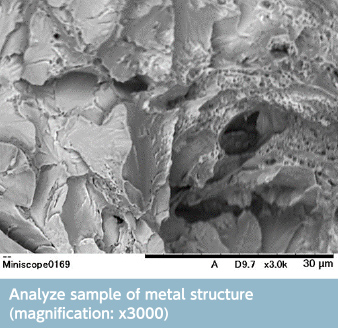

- Investigation of a metal structure level

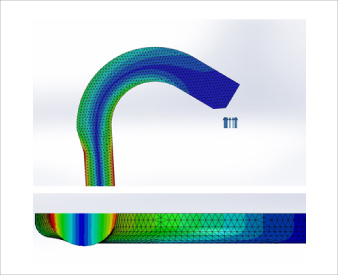

- Investigation of stress behavior by simulation

Please contact us for anything concerning fastening product investigation, development and research.

※ Currently, we are focusing on new product development for renewable energy.

R&D facilities

The observation of metal structure with high-magnification allows us to understand if the structure is in its normal state.

Micro level observation of the fracture surface allows us to determine the destruction causes and the usage situation.

●Specifications

| Observation magnification | x15 – x30,000 |

|---|---|

| Accelerating voltage | 5kV,15kV |

| Maximum sample size | φ70mm × thickness 50mm |

| Observation mode | Standard mode, Electrification reduce mode |

EDX evaluates the standard quantities of components in the product, and also evaluates the component variations of each part.

It can also study the fracture surface which could cause destruction.

●Specifications

| Detectable element | B5~U92 |

|---|---|

| Energy resolution | 161eV(Cu-Kα) |

| Quantitative analysis mode | Spectrum (point, surface) Line scan Element mapping |

It provides the information of metal structure and to investigate the structure normality.

●Specifications

| Observation magnification | x5 , x100, x200, x400, x500 |

|---|---|

| Observation method | Bright field, Dark field |

| Observation mode | Standard, Grain size measure (JIS G0551 / ASTM E112-96 / E1382-97) |

It enlarge up to x1,000, and get three-dimensional view by using a 3D image mode and depth synthesis. It also allows us to apply to a macro view observation of the object under investigation.

●Specifications

| Observation magnification | x1 – x1000 |

|---|---|

| Resolution | 2 million pixels, 4 million pixels, 8 million pixels, 18 million pixels |

| Observation mode | Depth Synthesis mode 3D image mode |

We investigate the hardness of microscopic range, and tells us the processing background.

It is useful for inspection test for the hardness of decarburization-carburizing threaded parts.

●Specifications

| Test power | 5gf,10gf,25gf,50gf,100gf, 200gf,300gf,500gf,1000gf |

|---|---|

| Load retention time | 5~99sec |

| Sample maximum height | 120mm |

| Sample maximum depth | 140mm |

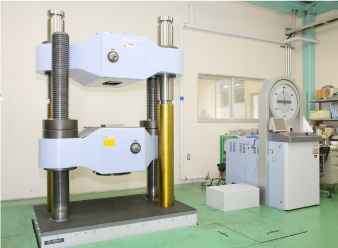

By exerting pressure on the object under investigation in several ways, it permits us to determine the proper specification of the product,

※ We have also a 1000kN Omnipotent tester. We select the tester machine depending on the object under investigation.

●Specifications

| Maximum load capacity | 3000kN |

|---|---|

| Diameter of bar for jaw | φ20~φ110 |

| Load speed | Max. 40mm / mm |

| Test mode | Tensile test / Compression test / Cycle test (Maximum setting cycle number 1000 times) |

It permits us to investigate the surface treatment efficiency on the product.

●Specifications

| Standard applications | ISO,IEC,JIS,ASTM |

|---|---|

With the simulation, we can determine the destruction causes and forces applied during product usage.

Major R&D achievements

| September 2014 | Japanese Mechanical Engineering Conference in Ibaraki “Resistance analysis of Rail hook bolt (Part 2)” |

|---|---|

| September 2013 | Japanese Mechanical Engineering Conference in Ibaraki “Structural steel material quenching and tempering conditions review” |

| August 2012 | Japanese Mechanical Engineering Conference in Ibaraki “Resistance analysis of Rail hook bolt” |

- Published in 2013

- Patent No. 174067 Joint fittings segment (co-application with other companies)

- Published in 2009

- Patent No. 019347 Bridge sleeper fixing hook bolt washer and packing

- Published in 2008

- Patent No. 025335 Bridge sleeper fixing hook bolt, washer and bridge sleeper

- Published in 2006

- Patent No. 002405 Rail first aid unit of the connecting track, and rail emergency treatment methods of the connecting orbit (co-application with other companies)

- Published in 2004

- Patent No. 162256 Removable underground pipe